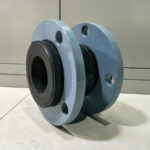

Carbon steel flange rubber joint

Description

Carbon steel flange rubber joint

Khớp nối chống rung cao su mặt bích thép carbon

Khái niệm: Các khớp nối cao su mặt bích bằng thép cacbon phun sơn được làm bằng các lớp cao su độc lập và vật liệu gia cường được lưu hóa với nhau sau khi đúc hoặc đúc. Mặt bích thép cacbon phun sơn có thể được làm với nhiều màu sắc khác nhau tùy theo nhu cầu khác nhau của khách hàng.

Spray-painted carbon steel flange rubber joints are made of independent rubber layers and reinforcement materials which are vulcanized together after moulding or moulding. Spray-painted carbon steel flanges can be made in different colors according to different needs of customers.

Features: Vibration absorption, noise reduction, high pressure resistance, good elasticity, large displacement, balance pipe deviation, easy installation

- DIMENSION: DN32mm-DN3000mm

- PRODUCT PRESSURE: 0.6-2.5 MPa

- FLANGE MATERIAL: carbon steel, stainless steel (304.316)

- SERVICE TEMPERATURE:– 40 degrees to 80 degrees (can also process high temperature resistant rubber joints)

- APPLICABLE MEDIA:acid, alkali, corrosion, oil, hot water, cold water, compressed air, compressed natural gas, etc.

PERFORMANCE

Installation does not require washers:

Carbon steel spray-painted rubber joints are equipped with vulcanized rubber flanges and fabrics integrated with pipes, which eliminates the need for gaskets in most applications. Check assembly instructions before installation. Steel wire or solid wire rope is embedded in the matrix and used as reinforcement for joints.

Light:

The rubber expansion joint is relatively light in weight, which helps to reduce the installation labor cost.

Reduce heat loss:

Rubber expansion joint can reduce heat loss and provide long-term maintenance-free service.

Flange:

Standard sprayed carbon steel. Forged flanges or cast carbon steel flanges are also available. Flange production standards can be made into EN, ANSI, JIS, AWWA, GOST, DIN standards or any specific size.

PRODUCT PARAMETERS

| Nominal Diameter(DN) | Length L | Axial displacement | Horizontal Isplacement | Angular deflection | ||

| mm | inch | mm | Extension | Compression | mm | (a1+a2) |

| 32 | 1¼ | 95 | 6 | 9 | 9 | 15º |

| 40 | 1½ | 95 | 6 | 10 | 9 | 15º |

| 50 | 2 | 105 | 7 | 10 | 10 | 15º |

| 65 | 2½ | 115 | 7 | 15 | 11 | 15º |

| 80 | 3 | 135 | 8 | 19 | 12 | 15º |

| 100 | 4 | 150 | 10 | 19 | 13 | 15º |

| 125 | 5 | 165 | 12 | 20 | 13 | 15º |

| 150 | 6 | 180 | 12 | 25 | 14 | 15º |

| 200 | 8 | 210 | 16 | 25 | 22 | 15º |

| 250 | 10 | 230 | 16 | 25 | 22 | 15º |

| 300 | 12 | 245 | 16 | 25 | 22 | 15º |

| 350 | 14 | 255 | 16 | 25 | 22 | 15º |

| 400 | 16 | 255 | 16 | 25 | 22 | 15º |

| 450 | 18 | 255 | 16 | 25 | 22 | 15º |

| 500 | 20 | 255 | 16 | 25 | 22 | 15º |

| 600 | 24 | 260 | 16 | 25 | 22 | 15º |

Reviews

There are no reviews yet.