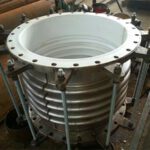

PTFE expansion joints

Description

PTFE expansion joints

Khớp nối chống rung kim loại lót PTFE

The outer body of the PTFE expansion joint is a stainless steel metal bellows that can withstand various concentrations of acid, alkali, salt, and the pressure of the stainless steel bellows and is not afraid of collision advantages. The piping system used for highly corrosive media compensates the displacement and installation deviation of thermal expansion and contraction, and reduces the vibration of the piping system.

Features: weather resistance, corrosion resistance, not easy to age

- NOMINAL DIAMETER: DN32mm-DN1000mm

- WORKING PRESSURE: 0.6-2.5Mpa

- WORKING TEMPERATURE: -40℃to 200℃

- APPLICABLE MEDIUM: water, steam, air, weak acid and alkali, oil, etc.

PERFORMANCE

Advantages:

1. It can be installed at the inlet and outlet of the pump or other high-frequency mechanical analysis to reduce or eliminate its vibration, improve the service life and sealing performance of the pipeline. It solves the problems that metal bellows can’t solve, reduces the cost of the enterprise, and improves the production efficiency. In addition, it can be used to absorb deviations between the design and the actual installation. It has the advantages of reliable operation, compact structure and strong compensation ability, resistance to corrosion of various media and long service life.

2. The structure has outer layer 304 stainless steel corrugated, can withstand the pressure of normal pipeline, lined with PTFE material, and PTFE is a polymer of tetrafluoroethylene. The English abbreviation is PTFE.

3. The PTFE expansion joints overcomes the shortage of corrosion resistance of the stainless steel metal bellows; it solves the shortcoming that the rubber composite metal bellow is difficult to withstand higher working pressure. In addition to strong corrosion resistance and high pressure, the product has the characteristics of high standardization, good versatility, strong interchangeability, anti-aging, reliable sealing and long service life.

Purpose :

The lining PTFE expansion joints has the advantages of low chemical activity, resistance to various chemicals, weather resistance, corrosion resistance, etc., and is not prone to aging. The lining PTFE expansion joints has strong anti-adhesiveness, low friction coefficient and excellent electrical characteristics.Under the condition of strong corrosive medium, the operating temperature is high, which can meet the working temperature range of -40℃to 200℃. All chemical media can meet this temperature range. Under the condition of strong corrosive medium, the operating temperature is high, which can meet the working temperature range of – 40 ~ 200 C. All chemical medium can meet the temperature range.

Principle of axial motion:

Axial movement is considered to be the elongation or compression of the pipe system on its longitudinal axis, which means that the total length of the expansion joint will extend or compress during the absorption movement. An axial expansion joint designed to absorb large motions can contain one, two or more bellows in one unit, and can also achieve greater motion by pretensioning or by installing multiple expansion joints on the pipe section. . Depending on the nominal diameter and length, the axial expansion joints are able to absorb small lateral and angular deviations as well as mounting tolerances. However, we recommend the use of the main function that should limit the axial expansion joint, otherwise its service life may be adversely affected.

Expanding knowledge:

1. Insulation: not affected by the environment and frequency, the volume resistance can reach 1018 ohm/cm, the dielectric loss is small, breakdown power.

2. High and low temperature resistance: The influence on temperature is not changed much, and the temperature range is wide. The temperature can be used from -190 to 260℃.

3. Self-lubricating: It has the smallest friction coefficient in plastic and is an ideal oil-free lubricating material.

4. Non-stick surface: Known solid materials can not adhere to the surface, it is a solid material with the smallest surface energy.

5. Resistance to atmospheric aging, radiation resistance and low permeability: long-term exposure to the atmosphere, surface and performance remain unchanged.

6. Non-combustibility: the oxygen limit index is below 90.

PRODUCT PARAMETERS

| Nominal diameter DN |

Quantity of ripple | Pressure level(Mpa) | Effective area of corrugated tube | Maximum external diameter size | Length | |||||

| 0.25 | 0.6 | 1 | 1.6 | 2.5 | (cm2) | (mm) | Flange JDZ/F | Connection tube | ||

| (mm) | JDZ/F | |||||||||

| Axial compensation (mm),f911 degree N/ram | (mm) | |||||||||

| 32 | 8 | 25/21 | 22/26 | 20/26 | 18/63 | 15/98 | 16 | 110 | 160/250 | 264/210 |

| 16 | 50/11 | 46/14 | 41/14 | 36/32 | 31/47 | 220 | 224/291 | 316/320 | ||

| 40 | 8 | 25/28 | 22/44 | 20/44 | 18/89 | 15/106 | 23 | 130 | 164/259 | 269/260 |

| 16 | 50/14 | 46/22 | 41/22 | 36/45 | 31/55 | 240 | 230/304 | 319/400 | ||

| 50 | 8 | 25/30 | 22/51 | 20/70 | 18/70 | 15/138 | 37 | 150 | 172/276 | 282/230 |

| 16 | 50/16 | 46/26 | 41/35 | 36/35 | 31/70 | 260 | 240/342 | 347/450 | ||

| 65 | 8 | 33/28 | 30/35 | 26/44 | 22/55 | 19/68 | 55 | 170 | 315/294 | 300/260 |

| 12 | 42/16 | 38/22 | 38/32 | 34/40 | 29/50 | 280 | 260/334 | 340/470 | ||

| 80 | 8 | 40/20 | 36/26 | 34/33 | 28/41 | 24/54 | 81 | 200 | 240/338 | 344/260 |

| 10 | 53/14 | 49/17 | 49/21 | 43/26 | 38/33 | 230 | 270/368 | 374/300 | ||

| 100 | 8 | 45/47 | 45/60 | 40/75 | 35/93 | 29/117 | 121 | 220 | 235/317 | 323/280 |

| 10 | 76/26 | 74/32 | 64/40 | 57/50 | 49/63 | 260 | 305/381 | 387/320 | ||

| 125 | 6 | 48/38 | 42/47 | 38/59 | 34/74 | 29/92 | 180 | 250 | 282/314 | 316/320 |

| 8 | 85/23 | 77/29 | 66/36 | 58/45 | 50/56 | 290 | 382/386 | 388/360 | ||

| 150 | 6 | 49/42 | 44/50 | 40/62 | 34/78 | 29/97 | 257 | 250 | 282/339 | 338/320 |

| 8 | 79/34 | 71/43 | 64/51 | 54/59 | 46/65 | 290 | 356/399 | 402/360 | ||

| 200 | 6 | 52/49 | 46/55 | 42/68 | 38/78 | 34/111 | 479 | 300 | 280/348 | 348/370 |

| 8 | 73/31 | 65/44 | 59/52 | 53/58 | 48/78 | 340 | 340/402 | 402/420 | ||

| 250 | 6 | 72/30 | 63/34 | 59/42 | 52/45 | 47/55 | 769 | 300 | 315/379 | 415/420 |

| 8 | 108/16 | 97/21 | 87/35 | 79/39 | 71/47 | 360 | 393/459 | 493/460 | ||

| 300 | 6 | 72/51 | 65/55 | 59/59 | 52/65 | 47/71 | 1105 | 340 | 366/427 | 466/488 |

| 8 | 108/32 | 97/35 | 87/37 | 79/41 | 71/45 | 400 | 464/525 | 564/520 | ||

| 350 | 6 | 72/58 | 65/62 | 59/67 | 52/74 | 47/81 | 1307 | 340 | 397/452 | 497/480 |

| 8 | 108/38 | 97/41 | 87/44 | 79/48 | 71/47 | 420 | 509/564 | 609/540 | ||

| 400 | 6 | 72/54 | 65/58 | 59/62 | 52/68 | 47/75 | 1611 | 340 | 412/478 | 512/480 |

| 8 | 108/36 | 97/39 | 87/43 | 79/47 | 71/52 | 420 | 522/588 | 622/560 | ||

| 450 | 6 | 108/32 | 97/35 | 87/37 | 79/41 | 71/45 | 1972 | 340 | 403/498 | 503/500 |

| 8 | 162/20 | 145/22 | 131/23 | 118/25 | 106/28 | 450 | 503/658 | 603/590 | ||

| 500 | 6 | 108/59 | 97/64 | 87/68 | 79/75 | 71/82 | 2445 | 340 | 431/523 | 531/500 |

| 8 | 162/34 | 145/37 | 131/39 | 118/43 | 106/48 | 450 | 531/665 | 631/600 | ||

| 600 | 6 | 108/74 | 97/80 | 87/85 | 79/94 | 71/103 | 3534 | 380 | 478/548 | 578/540 |

| 8 | 162/42 | 145/45 | 131/49 | 118/53 | 106/60 | 658/679 | 758/640 | |||

| 700 | 4 | 108/67 | 97/72 | 87/77 | 79/85 | 71/103 | 4717 | 1110 | 490 | 550 |

| 6 | 162/42 | 145/45 | 131/49 | 118/53 | 106/60 | 690 | 670 | |||

| 800 | 4 | 120/88 | 102/95 | 102/102 | 94/112 | 71/95 | 5822 | 1265 | 502 | 560 |

| 6 | 183/67 | 164/72 | 156/77 | 144/85 | 106/60 | 610 | 600 | |||

| 900 | 4 | 120/84 | 108/90 | 102/97 | 94/107 | 82/123 | 7620 | 1186 | 620 | |

| 6 | 183/60 | 164/65 | 156/69 | 144/76 | 125/93 | 720 | ||||

| 1000 | 4 | 120/91 | 108/98 | 102/105 | 94/116 | 82/117 | 9043 | 1286 | 690 | |

| 6 | 183/59 | 164/65 | 156/71 | 144/81 | 125/84 | 790 | ||||

Reviews

There are no reviews yet.