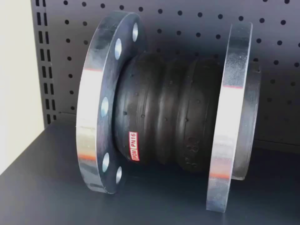

Khớp nối mềm chống rung cao su bụng kép EPDM

Description

Khớp nối mềm chống rung cao su bụng kép EPDM

EPDM double sphere rubber expansion joint

Khái niệm: Khớp nối giãn nở bụng kép EPDM mang lại nhiều ưu điểm và thường được sử dụng trong các đường ống để tránh hư hại cho các kết cấu xung quanh. Khớp nối mềm giãn cao su cầu kép EPDM giúp giảm bớt ứng suất nhiệt, giãn nở và co lại trong quá trình lắp đặt đường ống hoặc đường ống dẫn. Khớp nối co giãn cao su bụng đôi EPDM có thể chịu được nhiệt độ cao tới 110-130 độ C và kiềm, axit pha loãng. Đầu nối cao su cầu kép EPDM tiết kiệm năng lượng có thể chống lại bức xạ tia cực tím, thời tiết, thích hợp cho các ứng dụng ngoài trời.

EPDM double sphere rubber expansion joints offer many advantages and are usually used in pipes to prevent damage to surrounding structures. EPDM double sphere rubber expansion joints help to alleviate heat, extension and contraction stresses in pipeline or pipeline installation. EPDM double sphere rubber expansion joints can withstand temperatures as high as 110-130 degrees C and diluted alkali and acid. EPDM double sphere rubber connector energy-saving can resist ultraviolet radiation, weathering, suitable for outdoor applications.

Features: Vibration absorption, noise reduction, high pressure resistance, good elasticity, large displacement, balance pipe deviation, easy installation

- DIMENSION: DN32mm-DN800mm

- PRODUCT PRESSURE: 0.6-2.5 MPa

- PRODUCT MATERIAL: NR, EPDM, NBR, KFM, PTFE, CR

- WORKING TEMPERATURE:about – 50 +150

- SCOPE OF APPLICATION:weak acid and alkali, strong alkali, lime slurry, desulfurization, chemical plant sewage

PERFORMANCE

Can be used in both input side and absorption side:

EPDM rubber double sphere expansion joint can be used in the range of over 850 p.s.i. burst pressure and normal internal pressure 225 p.s.i. due to the combination of excellent forming technology and tough chemical fibers. In addition, EPDM double sphere rubber expansion joint can withstand the vacuum force generated on the conveying side and the suction side. Moreover, EPDM double sphere rubber expansion joint can be used even under high pressure, because its sphere is special spherical, and even pump connector will not contact the connecting bolt head.

Pipeline easy to install:

Because EPDM twin sphere rubber expansion joint shell is soft and easy to deform, although there are some deviations, the pipeline connection can be completed quickly and easily. When installed, transverse, axial and angular displacement can be generated, which is not limited by the non-centric pipes and the non-parallel flanges.

EPDM double ball rubber connectors help to absorb movement, which can prevent surrounding pipes or pipes from pulling, bending or leaking. This is a simple way to reduce maintenance costs, because replacing pipes or pipelines can be expensive.

Excellent ability to isolate sound and vibration:

The highly flexible matrix of EPDM double sphere rubber expansion joint isolates vibration and solid sound in all directions to prevent noise.

When working, it can reduce the noise transmission of the structure and has strong shock absorption ability..

Other advantages:

1) EPDM double sphere rubber expansion joints need neither gaskets nor packaging.

2) Because the flange is a loose fit type, EPDM rubber expansion joint can be installed on the pipeline without any difficulty.

3) Because EPDM double sphere rubber connectors absorbs the elongation and contraction of pipeline caused by temperature change, it can prevent the damage of pipeline system and equipment.

4) When pipes made of different engineering materials are connected with EPDM rubber expansion joints, it can prevent them from joining with EPDM rubber expansion joints, thus preventing them from electrolytic corrosion..

PRODUCT PARAMETERS

| Nominal Diameter(DN) | Length L | Diameter of the centralring of the bolt | Hole diameter quantitvd | Axial displacement | Horizontal Isplacement | Angular deflection | ||

| mm | inch | mm | mm | Extension | Compression | mm | (a1+a2) | |

| 40 | 1½ | 165 | 110 | 18-4 | 30 | 50 | 45 | 35º |

| 50 | 2 | 165 | 125 | 18-4 | 30 | 50 | 45 | 35º |

| 65 | 2½ | 175 | 145 | 18-4 | 30 | 50 | 45 | 35º |

| 80 | 3 | 175 | 160 | 18-8 | 35 | 50 | 45 | 35º |

| 100 | 4 | 225 | 180 | 18-8 | 35 | 50 | 40 | 35º |

| 125 | 5 | 225 | 210 | 18-8 | 35 | 50 | 40 | 35º |

| 150 | 6 | 225 | 240 | 22-8 | 35 | 50 | 40 | 35º |

| 200 | 8 | 325 | 295 | 22-8 | 35 | 50 | 40 | 35º |

| 250 | 10 | 325 | 350 | 22-12 | 35 | 60 | 35 | 30 |

| 300 | 12 | 325 | 400 | 22-12 | 35 | 60 | 35 | 30 |

| 350 | 14 | 330 | 460 | 22-16 | 35 | 60 | 35 | 30 |

| 400 | 16 | 330 | 515 | 26-16 | 35 | 60 | 35 | 30 |

| 450 | 18 | 330 | 565 | 26-20 | 35 | 60 | 35 | 30 |

| 500 | 20 | 350 | 620 | 26-20 | 35 | 60 | 35 | 30 |

| 600 | 24 | 350 | 725 | 30-20 | 35 | 60 | 35 | 30 |

| 700 | 28 | 350 | 840 | 30-24 | 35 | 60 | 35 | 30 |

| 800 | 32 | 400 | 950 | 30-34 | 35 | 60 | 35 | 30 |

Reviews

There are no reviews yet.