Ống nối mềm chống rung kim loại

Description

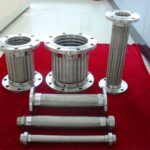

Ống nối mềm chống rung kim loại

Metal braided hose

Metal braided hoses are mainly composed of bellows, mesh sleeves, flanges and joints. The inner tube is a thin-walled stainless steel bellows having a spiral or toroidal shape. The outer sleeve of the bellows is made of stainless steel or steel strip according to certain parameters. The joints or flanges at the ends of the hose are matched to the union flanges of the customer’s piping. The metal hose is the main pressure-bearing part of the hose installed in the pressure line, and at the same time, the bellows is sheathed.

Features: light weight, simple structure, convenient installation and maintenance, large compensation

- NOMINAL DIAMETER: DN32mm-DN1000mm

- WORKING PRESSURE: 0.6-2.5Mpa

- WORKING TEMPERATURE: -15℃ to 300℃

- CONNECTION METHOD: flange type,groove type, loose type

- APPLICABLE MEDIUM: water, steam, air, weak acid and alkali, oil, etc.

PERFORMANCE

Advantage:

1. Flexible hose between pitches with small bending radius.

2.has good flexibility, no obstruction or stiffness.

3. the unit weight is light, the caliber consistency is good.

4.softness, repeated bending, and good flexibility.

5. Good corrosion resistance and high temperature resistance.

6.good wear resistance.

Application:

Due to the corrosion resistance, high temperature resistance and low temperature resistance of the metal hose (-196 ° C ~ +420 ° C), the weight is light, the volume is small, and the flexibility is good. Widely used in aviation, aerospace, petroleum, chemical, metallurgy, electric power, paper, wood, textile, construction, medicine, food, tobacco, transportation and other industries.

Pipe installation stress :

In complex piping systems, there are often difficulties due to space position conditions, resulting in installation difficulties: the formed pipe can not be loaded; bending over, coming over, making up the installed pipe will inevitably produce local Cold correction. Depending on the pipe diameter and the specific conditions on site, the amount of cold correction ranges from a few millimeters to tens of millimeters, and some hundreds of millimeters. Practice has proved that the larger the amount, the higher the internal stress, and the installation stress of these residues in the pipeline system is undoubtedly a great hidden danger.

Because the internal stress generated by bending and bending under the rated bending radius is very small, the metal hose can bring great convenience to the installation work, and also plays a certain role in ensuring the safe operation of the pipeline system. . This is the main reason why some piping systems must use metal hoses.

Performance:

Bellows: The bellows is the body of a metal hose. It is made of stainless steel and has corrosion resistance; hydroforming; it has strong flexibility, flexibility, bending and vibration resistance.

Net sleeve: The net sleeve is made up of a plurality of strands of wire crossing each other in a certain order, and is set on the outer surface of the metal bellows at a prescribed angle to play the role of strengthening and shielding. The net sleeve not only shares the static load of the metal hose in the axial direction and the radial direction, but also ensures the safe and reliable operation of the metal hose under the condition that the fluid flows along the pipeline to generate the pulse action, and at the same time, ensures that the corrugated portion of the hose is not directly Damaged by relative friction and the like.

PRODUCT PARAMETERS

| Norminal | Inside diameter | Outside diameter mm | Minimum bending radius | Maximum working pressure Mpa | |||

| Corrugated hose | With inner braided | Static | Dynamic | Inner braided | Outside braided | ||

| 8 | 8.8 | 13.2 | 14.4 | 50 | 110 | 15 | 20 |

| 10 | 11.7 | 16.5 | 17.7 | 65 | 145 | 15 | 20 |

| 15 | 13.5 | 19.5 | 21.1 | 80 | 180 | 15 | 20 |

| 20 | 20 | 27 | 28.6 | 120 | 270 | 10 | 15 |

| 25 | 27 | 34.5 | 36.1 | 160 | 360 | 63 | 10 |

| 32 | 32 | 40 | 41.6 | 175 | 400 | 40 | 63 |

| 40 | 39.6 | 52 | 53.6 | 225 | 510 | 40 | 63 |

| 50 | 49.7 | 62 | 63.6 | 280 | 640 | 30 | 50 |

| 65 | 61.2 | 80.2 | 81.8 | 410 | 915 | 30 | 50 |

| 80 | 79 | 96.3 | 97.9 | 486 | 1030 | 30 | 50 |

| 100 | 101.2 | 119.6 | 121.2 | 610 | 1340 | 25 | 40 |

| 125 | 124.1 | 145.3 | 146.9 | 700 | 1540 | 25 | 40 |

| 150 | 149.4 | 180.8 | 182.4 | 810 | 1780 | 25 | 40 |

| 200 | 176 | 240 | 243.2 | 1000 | 2000 | 25 | 40 |

| 250 | 248 | 290 | 294 | 1250 | 2500 | 25 | 40 |

| 300 | 298 | 350 | 354 | 1500 | 3000 | 16 | 25 |

| 350 | 347.6 | 400 | 404.8 | 1750 | 3500 | 16 | 25 |

| 400 | 397.6 | 460 | 464.8 | 2000 | 4000 | 16 | 25 |

Reviews

There are no reviews yet.