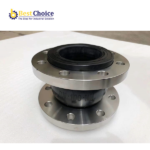

Single Sphere Rubber Expansion Joint

Tài liệu tham khảo : single rubber expansion joint – Khớp nối mềm cao su đơn

Description

Single Sphere Rubber Expansion Joint

Khớp nối mềm cao su đơn – Khớp nối giãn nở cao su đơn

Single Sphere Rubber Expansion Joint – khớp nối cao su

Khài niệm: Khớp nối mềm cao su hình cầu đơn được sử dụng chủ yếu để giảm độ rung, tiếng ồn, tính linh hoạt tốt và dễ sử dụng. Khớp nối mềm co giãn cao su hình cầu đơn, còn được gọi là khớp nối cao su đơn, khe co giãn cao su, đầu nối bi đơn, giảm chấn, giảm xóc đường ống, là loại mối nối đường ống có độ đàn hồi cao, độ kín khít cao, chịu lực trung bình và chịu được khí hậu.

Hiện tại sản phẩm khớ nối mềm cao su – khớp nối giãn nở đang được cty IWISU nhập khẩu và phân phối trên thị trường Việt Nam (VN) với đa dạng mẫu mã, phù hợp với nhu cầu cho từng ngành nghề trong các nhà xưởng, xí nghiệp,..Sản phẩm có sẵn tại cty

Single sphere rubber expansion joint is mainly used for reducing vibration, noise, good flexibility and easy to use.Single sphere rubber expansion join, also known as single ball rubber joint, rubber expansion joint, single ball connector , shock absorber, pipeline shock absorber, is a kind of pipeline joint with high elasticity, high air tightness, medium resistance and climate resistance.

- Features: Absorb vibration, reduce noise, high pressure resistance, good elasticity, large displacement, balance pipe deviation, easy installation

- DIAMETER: DN32mm-DN3000mm

- PRESSURE: 0.6-2.5 MPa

- APPLICABLE MEDIA: acid, alkali, corrosion, oil, hot water, cold water, compressed air, compressed natural gas, etc.

- MATERIAL: NR, EPDM, NBR, KFM, PTFE, CR

- FLANGE MATERIAL: carbon steel, stainless steel

rubber joint – khớp nối giãn nở cao su-1

rubber joint – khớp nối giãn nở cao su-2

rubber joint – khớp nối giãn nở cao su-3

rubber joint – khớp nối giãn nở cao su-4

PERFORMANCE

NR:

NR rubber expansion joints are characterized by high elasticity, high elongation, excellent tear resistance and electrical insulation, good wear resistance and drought resistance, good processability, easy adhesion to other materials, and superior to most synthetic rubber in comprehensive performance.

The disadvantages are poor oxygen and ozone resistance, easy aging and deterioration, poor oil and solvent resistance, low acid and alkali corrosion resistance and low heat resistance.

Use temperature range: about – 60 +80.

EPDM:

EEPDM rubber joint is also called EPDM rubber expansion joint. It is characterized by excellent ozone resistance, ultraviolet resistance, weather resistance and aging resistance, ranking first in general rubber. Electrical insulation, chemical resistance, impact elasticity is good, acid and alkali resistance, small proportion, can be filled with high coordination, heat resistance can reach 150 C, polar solvent-ketone, ester, but not resistant to aliphatic hydrocarbons and aromatic hydrocarbons, other physical and mechanical properties slightly inferior to natural rubber and superior to styrene-butadiene rubber.

The disadvantage is that self-adhesive and mutual-adhesive are very poor, and it is not easy to bond.

Use temperature range: about – 50 +150.

NBR:

NBR rubber joint is also called NBR rubber connector. It is characterized by excellent gasoline and aliphatic hydrocarbon oil resistance, second only to fluorine rubber, and superior to other general rubber. Good heat resistance, air tightness, wear resistance and water resistance, strong bonding force.

The disadvantages are poor cold and ozone resistance, low strength and elasticity, poor acid resistance, poor electrical insulation and poor polar solvent resistance.

Use temperature range: about – 30 +100.

CR:

EChloroprene rubber (CR) joints have excellent anti-oxygen, anti-ozone, non-flammability, self-extinguishing after ignition, oil resistance, solvent resistance, acid and alkali resistance, aging resistance, good air tightness and other advantages; their physical and mechanical properties are also better than natural rubber, so they can be used as general rubber and special rubber.

The main shortcomings are poor cold resistance, large proportion, high relative cost, poor electrical insulation, easy to stick and roll, easy to scorch and easy to stick mold in processing. In addition, raw rubber has poor stability and is not easy to preserve.

Use temperature range: about – 45 +100.

WORKING PRINCIPLE

| Nominal Diameter(DN) | Length L | Axial displacement | Horizontal Isplacement | Angular deflection | ||

| mm | inch | mm | Extension | Compression | mm | (a1+a2) |

| 32 | 1¼ | 95 | 6 | 9 | 9 | 15º |

| 40 | 1½ | 95 | 6 | 10 | 9 | 15º |

| 50 | 2 | 105 | 7 | 10 | 10 | 15º |

| 65 | 2½ | 115 | 7 | 15 | 11 | 15º |

| 80 | 3 | 135 | 8 | 19 | 12 | 15º |

| 100 | 4 | 150 | 10 | 19 | 13 | 15º |

| 125 | 5 | 165 | 12 | 20 | 13 | 15º |

| 150 | 6 | 180 | 12 | 25 | 14 | 15º |

| 200 | 8 | 210 | 16 | 25 | 22 | 15º |

| 250 | 10 | 230 | 16 | 25 | 22 | 15º |

| 300 | 12 | 245 | 16 | 25 | 22 | 15º |

| 350 | 14 | 255 | 16 | 25 | 22 | 15º |

| 400 | 16 | 255 | 16 | 25 | 22 | 15º |

| 450 | 18 | 255 | 16 | 25 | 22 | 15º |

| 500 | 20 | 255 | 16 | 25 | 22 | 15º |

| 600 | 24 | 260 | 16 | 25 | 22 | 15º |

Reviews

There are no reviews yet.