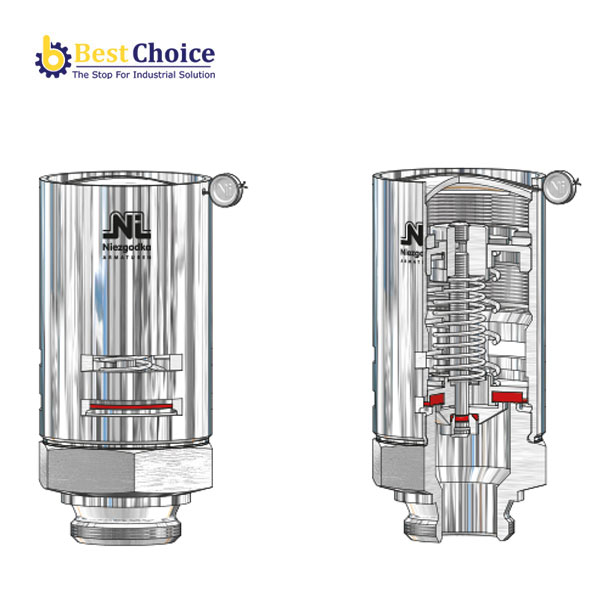

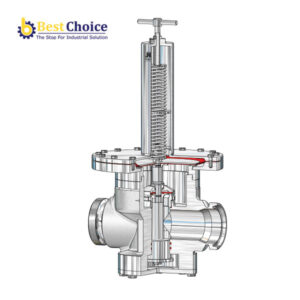

Type 90 Vacuum-and-Pressure-Relief-Valve

Description

Type 90 Vacuum-and-Pressure-Relief-Valve

Type 90 Vacuum-and-Pressure-Relief-Valve

| Standard version: | |||

|---|---|---|---|

| Material: | Inlet body | / | Bonnet pipe |

| Type 90.2: | 1.4571 | / | 1.4301, 1.4541 |

Elastomere

| EPDM 1) | EPDM | EPDM | APTK ®

Ethylen-Propylen- Dien-Kautschuk |

≤ 16 bar

– 40°C to +120°C – 40°C to +140°C 2) |

< 120 bar

– 40°C to +140°C – 40°C to +150°C 2) |

≤ 25 bar | Good resistance against a lot of chemicals, hot water, steam, alkaline solution, acids, alcohol. Average mechanical characteristics.

Ozone resistant, not oil resistant. |

| FEPM | FEPM | – | CHEMFLON ®

Tetrafluoroethylen, Propylene-Copolymer |

– | < 63 bar

– 5°C to +230°C |

≤ 25 bar | For highly stressed seals with excellent performance both

Against water / steam as well as against oils. |

| FPM 1) | FPM | FKM | Viton ® Fluor-Kautschuk | ≤ 25 bar

– 20°C to +200°C |

< 200 bar

– 20°C to +200°C |

≤ 40 bar | Good resistance against a lot of chemicals, mineral oil, hot air, acid.

Average to good mechanical characteristics. |

| FFKM | – | FFKM | Kalrez ® Perfluor-Kautschuk | ≤ 25 bar

– 30°C to +260°C |

< 120 bar

– 30°C to +260°C |

≤ 40 bar | Very good resistance against a lot of chemicals, oxygen, ozone, mineral oil.

Good thermal and mechanical characteristics. |

| FVMQ | – | – | Silastic Fluorsilikon-Kautschuk | < 10 bar

– 60°C to +200°C |

< 10 bar

– 60°C to +200°C |

< 25 bar | Good resistance to oils, fuels and solvents. |

| PUR 1) | AU | AU | Vulkollan ® Polyurethan | ≤ 30/35 bar

– 30°C to + 80°C |

– | < 35 bar | Good resistance against a lot of chemicals, hydraulic oil, alcohol, fuel.

Very good mechanical characteristics. |

| NBR 1) | NBR | NBR | Acrylnitril-Butadien- Kautschuk | – |

– 20°C to +120°C |

< 25 bar | Good mechanical properties in comparison with other elastomers, a higher abrasion resistance. |

| Silikon | VMQ | VMQ | Silikon | < 6 bar

– 60°C to +200°C |

< 10 bar

– 60°C to +200°C |

≤ 25 bar | Good resistance against hot gas and air. Average mechanical characteristics. |

| ULT | – | – | Ultrathan ® | – | ≤ 25 bar |

| Nylon 1) | PA | PA | Nylon ® Polyamid | ≤ 120 bar

do 8 ≤ 50 bar – 40°C to + 80°C |

– | ≤ 160 bar | Good resistance against a lot of chemicals, fuel, cooling liquid, silicone oil.

Good mechanical characteristics. |

| PEEK 1000 | – | – | Ketron | 40 – 900 bar

– 60°C to +250°C |

– | < 200 bar | Very good resistance against a lot of chemicals. Very good thermal and mechanical characteristics. |

| PTFE 1)

PTFE/GL |

PTFE | PTFE | Teflon ® Polytetrafluorethylen | ≤ 15/25 bar

– 200°C to +260°C |

– | ≤ 50 bar | Good resistance against chemicals, acid, alkaline solution, solvent, oil.

Good thermal and average mechanical characteristics. |

| PVDF | – | – | Polyvinylidenfluorid | ≤ 45 bar

– 40°C to +150°C |

– | ≤ 100 bar | Very good resistance against chemicals, gasiform oxygen.

Very good mechanical characteristics. |

| RCH 1000 | PE | PE | Polyethylen (PE) | ≤ 45 bar

– 270°C to + 80°C |

–

– 30°C to + 80°C |

≤ 50 bar | Good resistance against a lot of chemicals, cryogenic media.

Good mechanical characteristics. |

| Vespel | – | – | Vespel ® Polyimid | 40 – 500 bar

– 270°C to +250°C |

– | ≤ 200 bar | Very good resistance against CO2. Very good thermal and mechanical characteristics. |

Reviews

There are no reviews yet.